Tech vs. Tech: Microgravity reactors vs. 3D bioprinting ... in space!

As space exploration advances, biotechnology is a promising frontier, notably for matters of life support, but also for more efficiently leveraging resources in space environments.

Thanks to the International Space Station’s monopoly on space experimentation, the latter market has been almost completely concentrated in the US. So, given the ISS's imminent retirement, countries are racing to launch their own space stations. China plans to launch the Shenzhou 15 specifically for research. And the US and Russia have intents on replacing the ISS.

More space stations means more capacity to conduct experiments in zero gravity, more variety in techniques (since national experimental regulations differ), more technologies to invest in that result from those experiments, and more high-impact innovation … in theory, anyway.

Many contending countries hope their own commercial stations could pave the way for space tourism and its prospective multibillion dollar market. But a major competitive edge also stands to be gained in dominating zero-gravity medicine and drug manufacturing.

In this Tech vs. Tech, we explore microgravity bioreactors and 3D bioprinting, considering their potential applications in the new space race.

THE TECHNOLOGIES

Microgravity bioreactors are containers or chambers designed to culture and study biological samples—cells, tissues, or microorganisms—in conditions of reduced gravity or weightlessness.

Microgravity can lead to unique biological responses and cellular behaviours unobserved under normal gravity. It can facilitate more uniform growth in cells, leading to healthier and more robust tissue. It can also get cells to behave as they would in a human body, an often vital condition for regenerative medicine and organ transplantation. Bioreactors can either be directly deployed on spacecrafts, or microgravity can be simulated on Earth.

3D bioprinting is an additive manufacturing technique for producing three-dimensional biological structures, using living cells and biomaterials. In simple terms, it uses living cells to “print” tissues and organs. While the technology has made significant strides on Earth, the potential for bioprinting in space is equally exciting: It facilitates uniform cell distribution and the manufacture of multicellular, complex tissue constructs, which can serve as models in basic research as well as transplantable skin grafts.

CURRENT USES

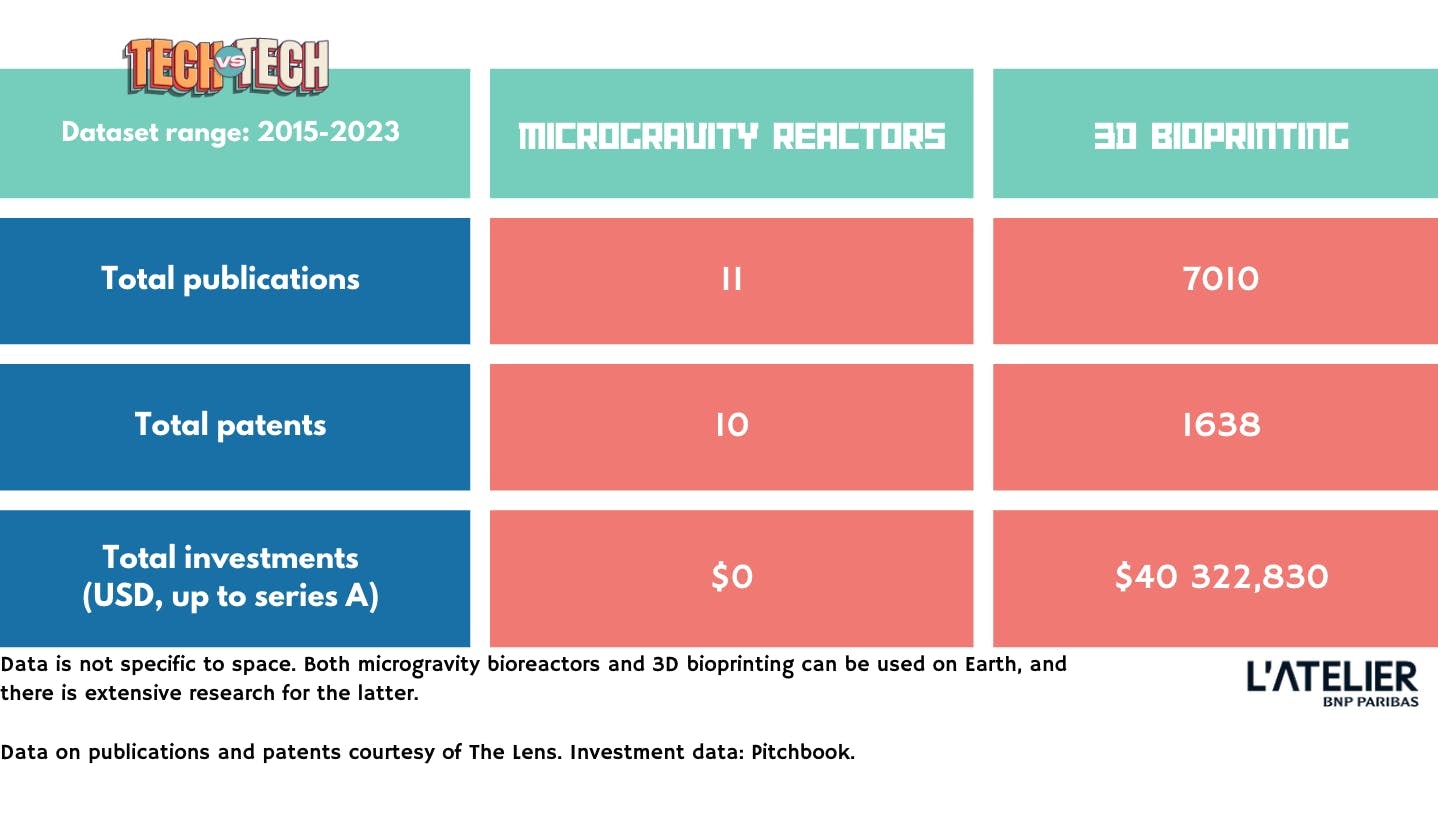

Microgravity bioreactors have been used in scientific research since the ‘80s. Due to challenges in fluid control, sensor size, sample volume, and disruptions to the mediums and cultures, commercial availability and widespread adoption remain limited (see table below).

But the tech shows promise in the field of tissue engineering. Microgravity has been shown to enhance the therapeutic effect of stem cell transplantation, and to improve the accuracy of disease modelling and personalised drug testing.

Meanwhile, 3D bioprinting in space is in its infancy; initial experiments were publicly announced in 2016. Yet it shows potential in soft and complex tissue printing, such as for blood vessels or cardiac tissues.

Within Earth’s gravity, such bioprinted structures require support—in the form of scaffolds—to avoid collapse during printing. The scaffolds are good for supporting thick tissues, but can damage vascular networks and soft tissue. They are utterly unnecessary in space microgravity. 3D bioprinting in space could thus, among other uses, help overcome organ donor shortages.

AND THE WINNER IS...

As space agencies and private companies continue investing in space technologies, a combination of microgravity bioreactors and 3D bioprinting may provide the most fruitful solutions as we delve into long-term space travel and exploration.

By culturing human cells in bioreactors onboard the International Space Station (ISS), researchers gained insight into the bone density loss or muscle atrophy that occurs in microgravity. This information will be used for future space missions, to monitor astronaut’s physical health, and find solutions to mitigate the negative impact of microgravity.

3D bioprinting holds promise for creating custom-tailored tissues and organs for astronauts, eliminating the need for lengthy organ donation waits, and addressing medical emergencies during extended missions. It could also enable the food production from cell-based agriculture, ensuring sustainable and renewable food sources for future space travellers.

Considering the variety and the potential for both on-Earth and in-space applications, we have no qualms about calling this Tech vs. Tech a draw.

Data on publications and patents courtesy of The Lens. Investment data: Pitchbook.

21 Mar 2024

-

Aurore Geraud

Illustration by Thomas Travert.

Get the future in your inbox once a week.

02/03

Related Insights

03/03

L’Atelier is a data intelligence company based in Paris.

We use advanced machine learning and generative AI to identify emerging technologies and analyse their impact on countries, companies, and capital.