Tech vs. Tech: Bioleaching vs. phytomining

To ensure European climate and digital objectives are met by 2030, developing eco-friendly alternatives to conventional practices is now a priority for every industry.

With the launch of the Critical Raw Materials Act in March 2023, industries involved in developing electric vehicles, wind and solar energy, robotics or semiconductors must all do their part to lessen “the EU's dependency on imported critical raw materials by diversifying and securing a domestic and sustainable supply.”

The Act makes it necessary to:

- Identify and integrate alternative advanced materials, capable of delivering the same results as existing critical ones within targeted technologies; or

- Completely reform the current critical raw materials lifecycle, from extraction to recycling.

One area that has captured research and environmental attention is that of mining methods. The Act seeks to ensure that at least 10 percent of critical resource extraction occurs in Europe. We can thus expect funding and advantageous policies to intensify mining activity within the EU.

However, traditional mining methods are known for being resource-intensive. In some cases they have detrimental impacts, both social (human rights, corruption, geopolitics) and environmental (water use, soil contamination).

In this Tech vs. Tech, we explore two innovative approaches to mining: bioleaching and phytomining, both of which offer promising green alternatives.

THE TECHNOLOGIES

Bioleaching is part of the centuries-old biohydrometallurgy field, which uses the reactions of microorganisms to trigger mineral dissolution and facilitate the recovery of metals. The process involves introducing specific bacteria or fungi into ore, which breaks down minerals and releases the desired elements. Advancements in microbiology have made it viable for large-scale industrial application. Not only does bioleaching minimise the need for energy-intensive processes; it could offset 34 percent of annual carbon emissions in the mining industry if applied to all mines.

Phytomining leverages the extraordinary abilities of certain plants to absorb metals from soil. These plants, known as hyperaccumulators, evolved in metal-rich environments and can thus accumulate high concentrations of metals in their tissues. When cultivated on mineral-rich lands, then harvested and processed, the metals within them can be extracted. Phytomining offers a unique opportunity to extract metals from low-grade ores or mine tailings, turning previously unviable sites into potentially valuable resources.

CURRENT USES

Both approaches have advantages and challenges. Bioleaching is highly effective at extracting a wide range of metals, including copper, gold, and uranium. It requires minimal infrastructure, and can be implemented in regions where conventional mining is unfeasible. But the process is slow, and sensitive to factors like temperature, pH levels, and microbial activity, which can affect efficiency. There is also a risk of water and soil contamination; toxic chemicals can be produced during bioleaching, which defeats its purpose.

Phytomining is a non-invasive, low-cost method for metal extraction. It can be employed wherever plant growth is possible, and harvested plants can be used for various purposes, including bioenergy production or removing heavy metals from contaminated sites. But like bioleaching, phytomining is slow, and remains in the early stages of development. Further research needs making to optimise plant selection, growth conditions, and metal recovery methods.

AND THE WINNER IS…

In the race between bioleaching and phytomining, it’s hard to call a winner. Each technology offers distinct advantages and can be applied in different contexts.

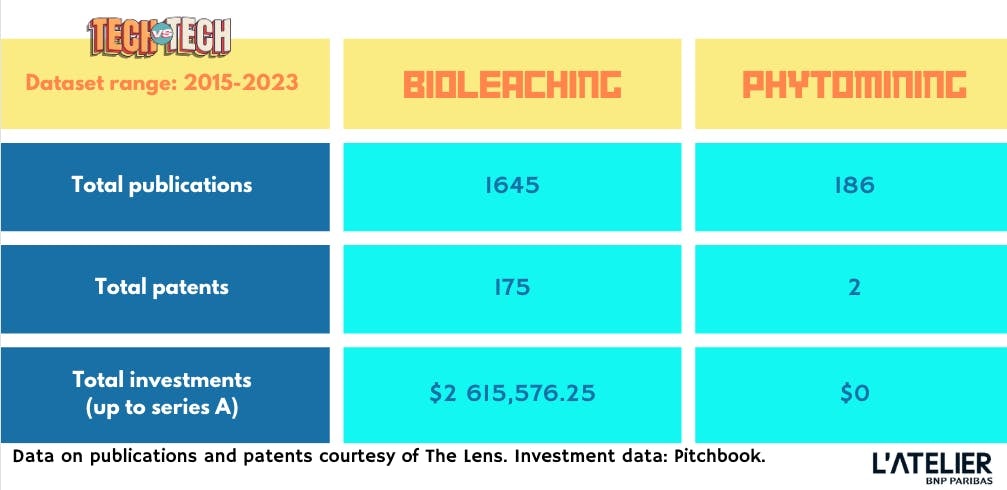

But the adoption of such green mining technologies goes beyond environmental benefits. For example, bioleaching—a more established technique (see chart above)—can contribute to the circular economy by enabling the recovery of valuable metals from electronic waste or discarded materials, reducing reliance on primary mining.

Both could create new economic opportunities in regions dependent on conventional mining, fostering sustainable development and job creation. The technologies appear complementary and shouldn't be treated in a zero-sum manner. A combination of both techniques, coupled with the EU’s recent due diligence law, will help the mining industry mitigate its varied human rights and environmental limitations with welcome—and necessary—flexibility.

Data on publications and patents courtesy of The Lens. Investment data: Pitchbook.

23 Nov 2023

-

Aurore Geraud

Illustration by Thomas Travert.

Get the newsletter: Every week, another chance to beat the curve.

02/03

Related Insights

03/03

L’Atelier is a data intelligence company based in Paris.

We use advanced machine learning and generative AI to identify emerging technologies and analyse their impact on countries, companies, and capital.